What Is The Loading Method Of Fixture?

1. Selection of fixtures

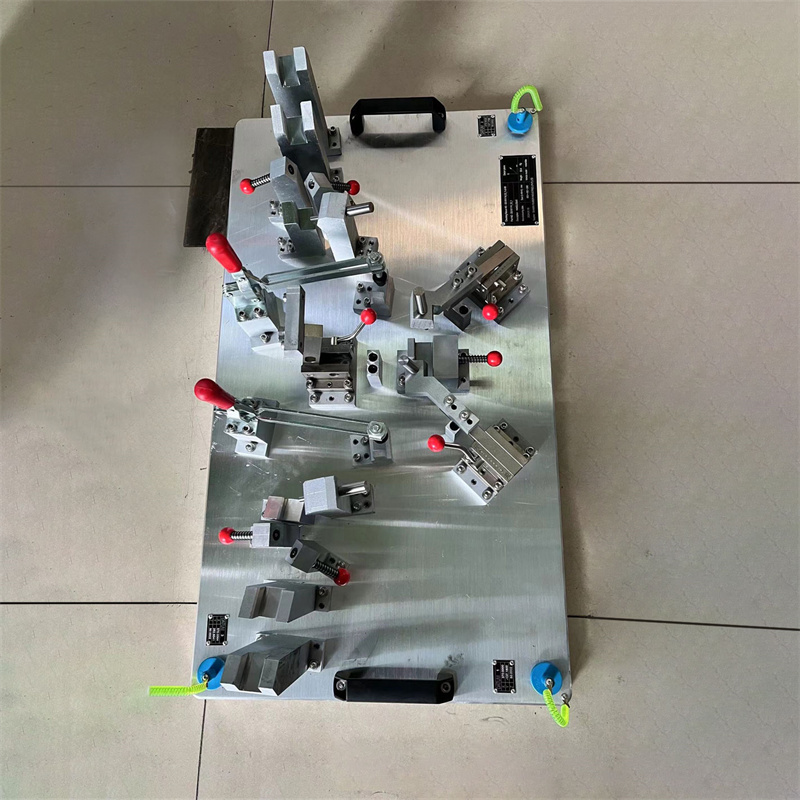

The selection of fixtures for CNC machining needs to meet the following requirements: First, the accuracy and rigidity of the fixture must meet the requirements; second, the positioning of the fixture must be accurate. When selecting a fixture, the following points are usually considered:

1) Try to use adjustable fixtures, combination fixtures and other general fixtures, so that the scope of application will be relatively large

2) Consider using special CNC machining fixtures only in batch production, and the structural design should be as simple as possible

3) Loading and unloading workpieces should be quick and convenient to reduce the downtime of the machine tool.

4) The fixture installation on CNC machining should be accurate to ensure that the workpiece is processed in the correct position.

2. Types of fixtures

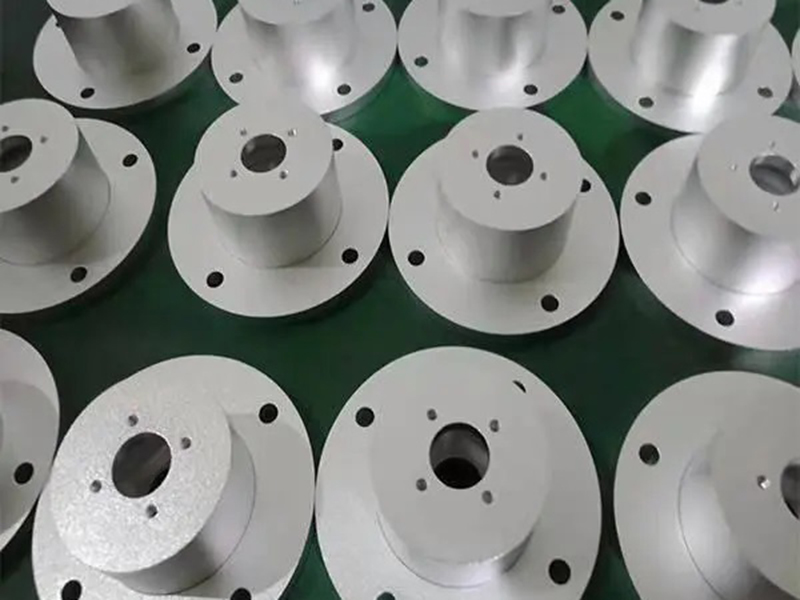

There are two main types of fixtures on CNC lathes: one is used for disc or short shaft parts, the workpiece blank is clamped in a chuck with adjustable jaws (three-jaw, four-jaw), and the workpiece is rotated by the chuck; the other is used for shaft parts, the blank is installed between the spindle top and the tailstock top, and the workpiece is rotated by the toggle chuck on the spindle.

The fixtures on CNC milling machines are generally installed on the workbench, and their forms can be varied according to the characteristics of the workpiece being processed. For example: universal bench vise, CNC indexing turntable, etc.

3. Installation of parts

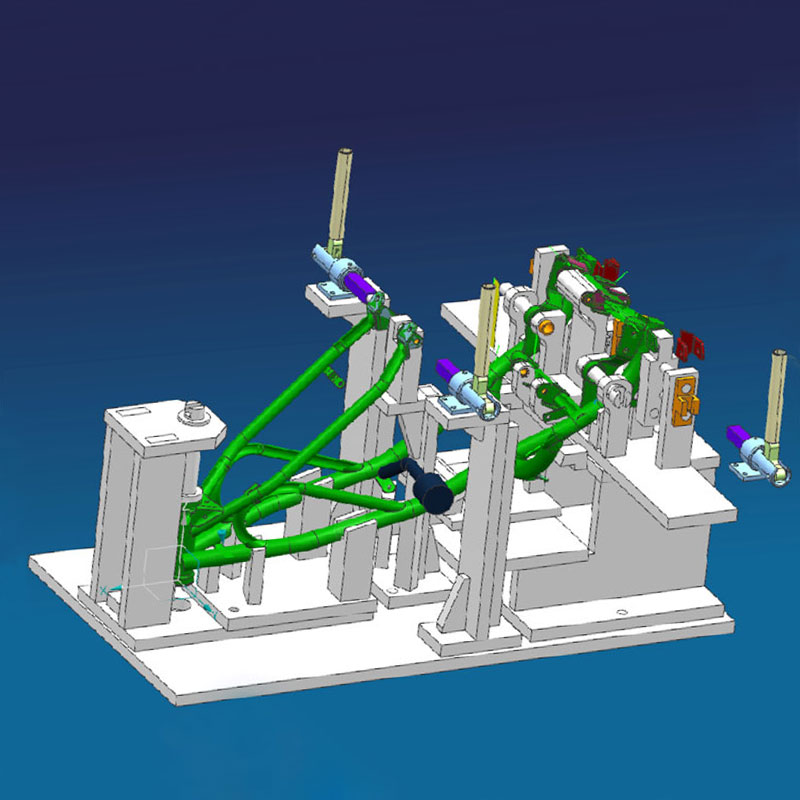

The installation method of parts on CNC machine tools is the same as that of ordinary machine tools. It is necessary to reasonably select the positioning reference and clamping scheme, and pay attention to the following two points:

1) The reference of design, process and programming calculation should be unified, so that the design is more accurate when used.

2) Minimize the number of clamping times, which can reduce the occurrence of errors