Get accurate quotes quickly

Just complete the following 3 steps

Prepare your drawings

Send us your 3D drawings in STP, STL, or CAD format.

SELECT materials and processes

Select the material, tolerance, and process you want, and you will receive timely feedback on manufacturability.

GET A QUOTE ONLINE

Get a quote and place an order.

Our Service

Dedicated to the industrial metal pipe fittings processing industry for over 20 years, with a wide range of categories, specifications, and multiple materials, one-stop procurement, ensuring peace of mind when buying and safe use.

Technical research and development

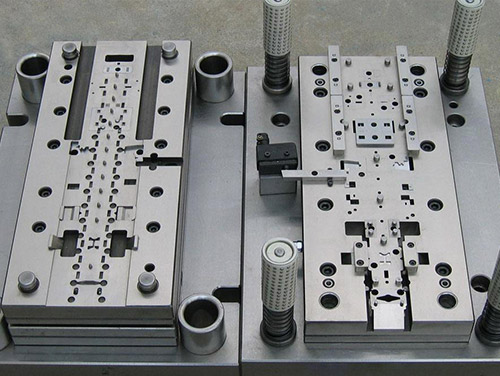

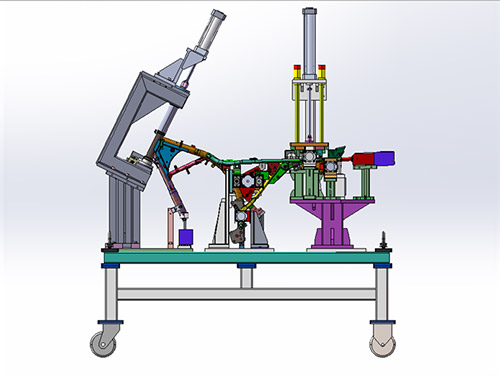

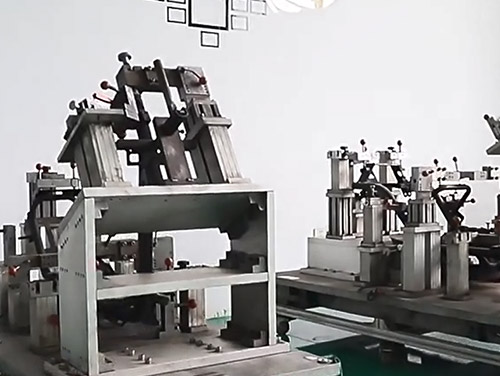

Focusing on various difficult hardware molds, welding fixtures, and inspection tools, integrating design, development, manufacturing, sales, and after-sales service.

Integrated research and development, design, and manufacturing

The company attaches great importance to the production technology and development research of industrial components and molds, and has a team of experienced and skilled senior engineers and engineers to provide you with services from mold design, processing, mold development, mold manufacturing, product testing, etc. After years of research and development and technical accumulation, a series of core technologies have been formed.

Mold review

Before opening the mold, technicians will analyze and optimize the design scheme based on the precise filling liquid and solidification defects calculated by professional tools, reduce the number of mold tests, lower production costs, and improve customer satisfaction.

High standard quality testing

A high-precision three coordinate measuring instrument is used to measure the dimensions of various parts of the product, reducing deviations and ensuring stable quality. All molds have been validated through trial production, and through the process of small-scale trial production, problems have been fully identified and thoroughly improved to prevent them from being brought to the customer's mass production stage, ensuring that the mold size is in place and improving mass production.

Customer Case

OEM

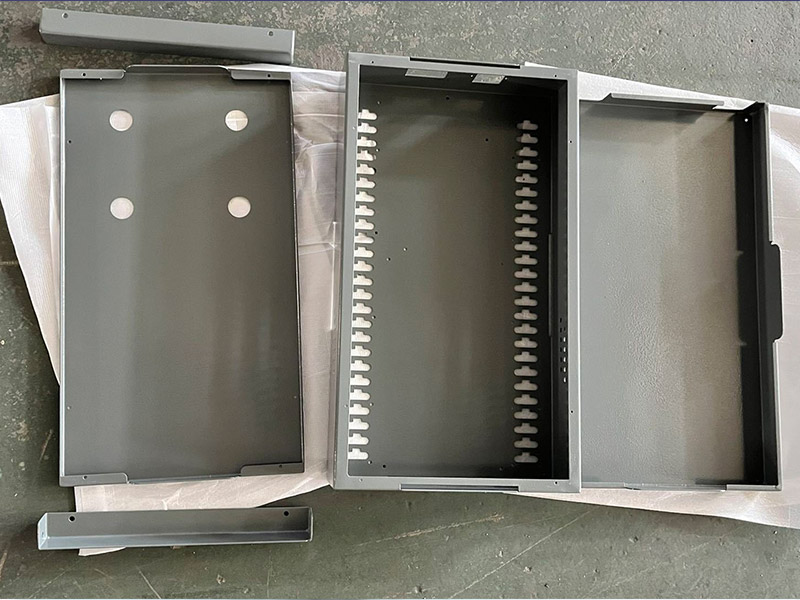

X-ray imaging device

Sheet metal structural components

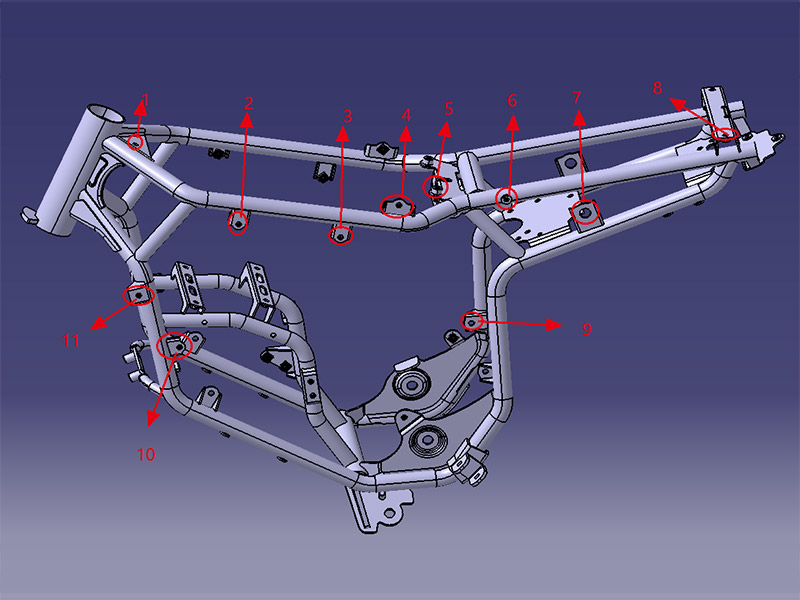

Electric motorcycle frame

Electric motorcycle frame

Electric motorcycle assembly

Bus handrail pipe

Welded pipe

FIXTURE

Cold storage piping

Aluminum CNC Parts

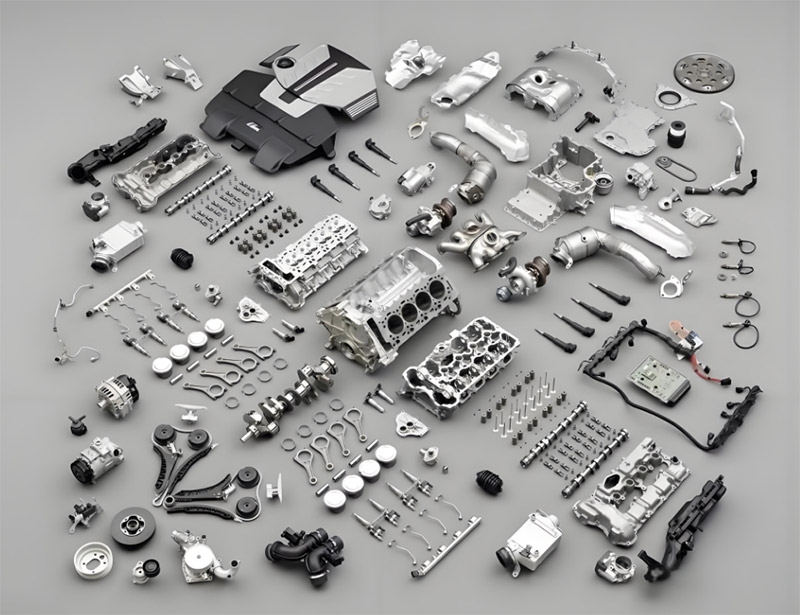

Auto Parts

Unmanned car compartment