The Main Application Areas Of Laser Cutting In Sheet Metal Processing

Laser cutting has a wide range of applications in sheet metal processing, mainly because it provides high-precision, efficient and customized cutting solutions. The following are some of the main application areas of laser cutting in sheet metal processing:

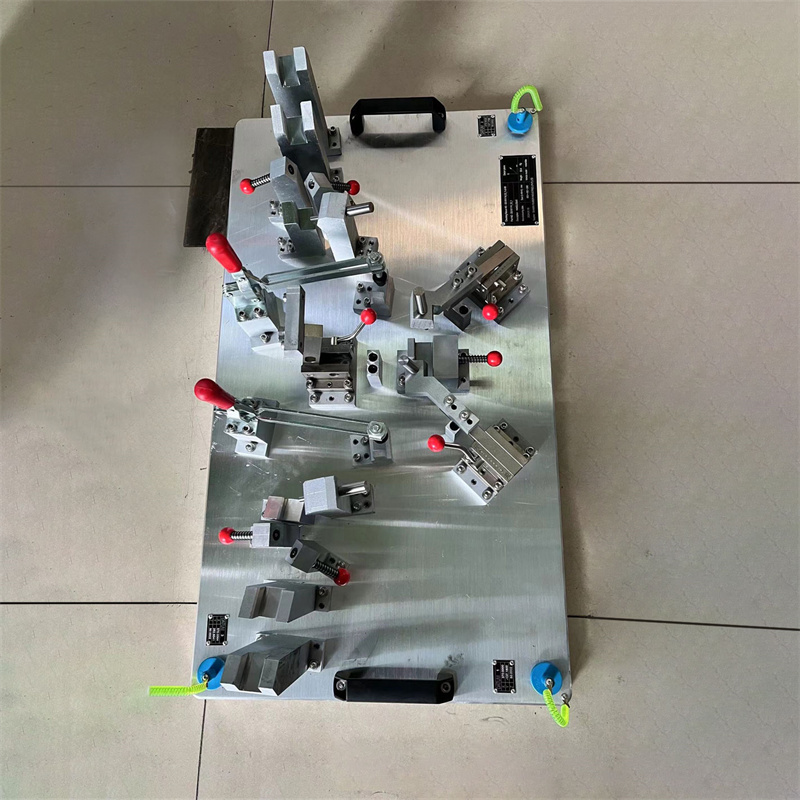

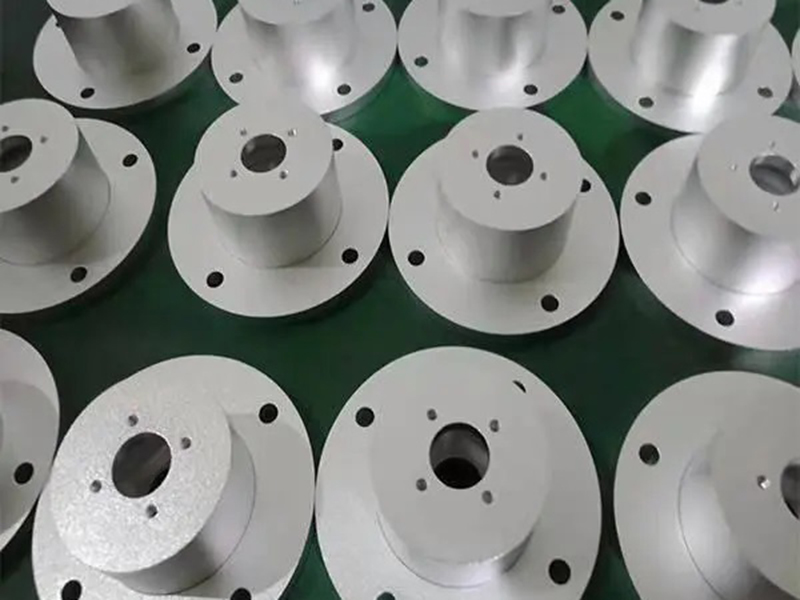

1. Metal parts manufacturing:

Laser cutting can be used to manufacture a variety of metal parts, including mechanical parts, electronic housings, bases, brackets, etc. It can accurately cut complex shapes and holes to ensure the size and quality of parts.

2. Automation equipment and machine manufacturing:

Automation equipment and machines usually require parts with high precision to ensure their normal operation. Laser cutting can provide the production of these precision parts.

3. Electronic and communication equipment:

Electronic equipment, communication equipment and servers usually require housings and panels to protect internal components and provide information identification. Laser cutting can be used to produce these housings and panels, and can cut precise openings and holes to accommodate components.

4. Medical equipment:

Medical equipment manufacturing requires parts with high precision and hygiene standards. Laser cutting can produce housings, brackets and other parts of medical equipment.

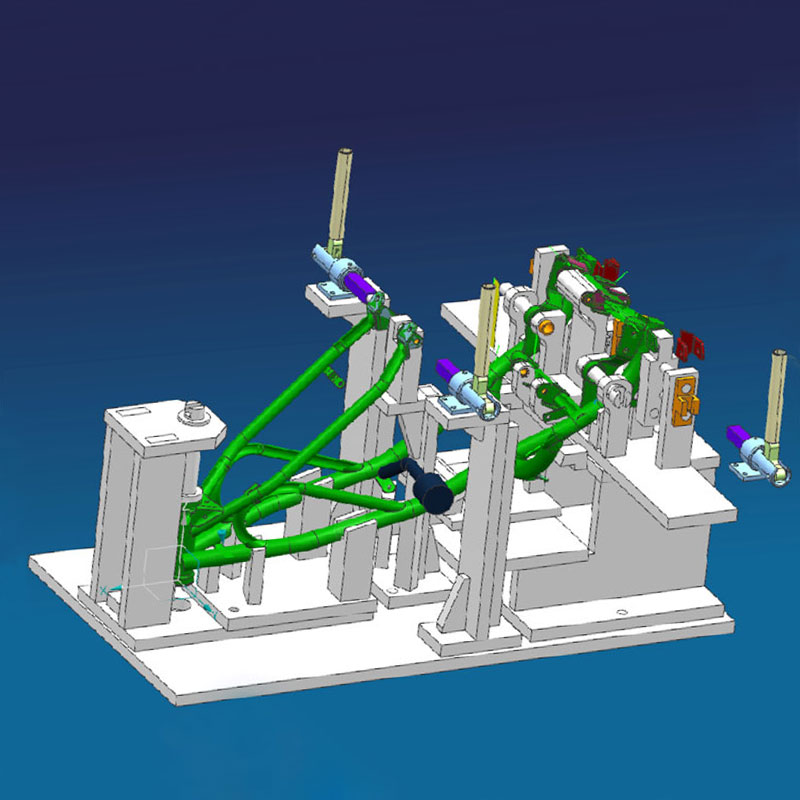

5. Automobile industry:

Automobile manufacturing requires a variety of sheet metal parts, such as body parts, exhaust pipes, chassis covers, etc. Laser cutting can be used to produce these parts to ensure their quality and precision.

6. Aerospace:

The aviation and aerospace fields require precision parts to ensure the safety and performance of aircraft and spacecraft. Laser cutting can be used to produce aerospace parts.

7. Architecture and architectural decoration:

Laser cutting can be used to manufacture metal components, railings, carved panels, etc. in architecture and architectural decoration.

8. Advertising signs and decoration:

Laser cutting can be used to make exquisite advertising signs, decorative panels and artworks.

In short, laser cutting is widely used in sheet metal processing because it can provide high-precision, efficient and customized cutting solutions for multiple industries, thus promoting the development of modern manufacturing and engineering.